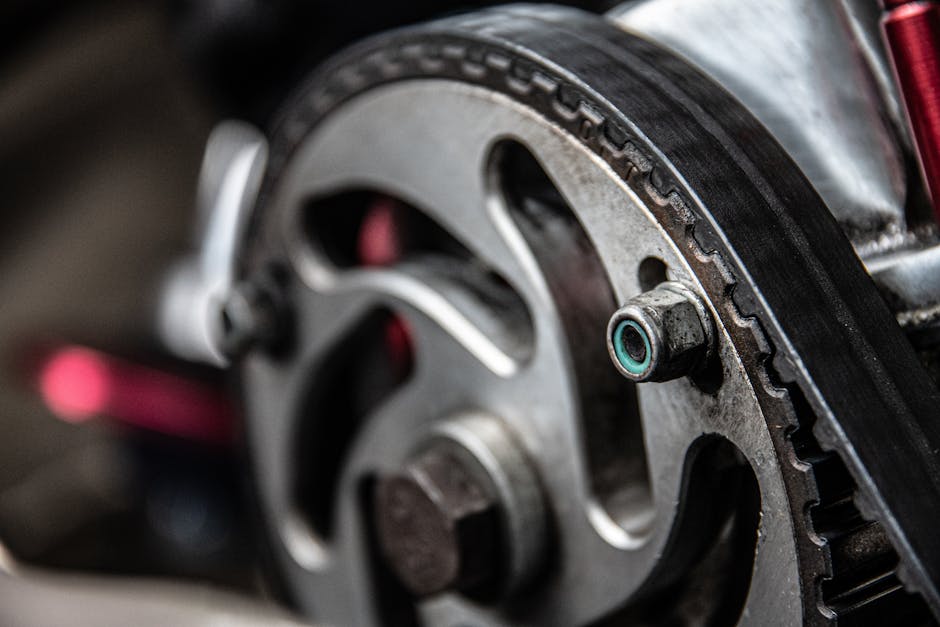

Fabrication Quoting Software: Key to Efficient Production Planning

Fabrication quoting software plays a pivotal role in the realm of efficient production planning. As manufacturers and fabricators seek greater control and precision in their operations, the implementation of advanced software solutions has become imperative.

This software empowers businesses with streamlined production workflow, heightened accuracy in cost estimation, real-time tracking of materials and labour, seamless integration with CAD/CAM systems, automated quoting and proposal generation, and enhanced resource utilisation and scheduling.

By leveraging these capabilities, businesses can attain a comprehensive view of their production processes and exercise greater control over their operations.

This introduction aims to explore the pivotal role of fabrication quoting software in enabling efficient production planning and its impact on organisational success.

Key Takeaways

- Integration of fabrication quoting software improves efficiency and workflow optimisation in manufacturing facilities.

- Advanced fabrication quoting software enhances cost estimation accuracy through real-time pricing data and predictive modelling.

- Real-time material and labour tracking enables optimal inventory management and improves resource allocation.

- Seamless integration with CAD/CAM systems streamlines production planning and eliminates errors caused by manual data input or conversion.

Streamlining Production Workflow

The implementation of a robust fabrication quoting software is essential for streamlining the production workflow in manufacturing facilities. By integrating this software, manufacturing companies can achieve improved efficiency and workflow optimisation.

This technology allows for the automation of various processes, including generating quotes, tracking orders, and managing inventory, leading to a more streamlined production workflow. With the ability to quickly and accurately generate quotes, production planning becomes more efficient, reducing lead times and improving overall operational productivity.

Additionally, fabrication quoting software facilitates better communication between different departments, ensuring that everyone is on the same page regarding production schedules and requirements. This level of coordination is crucial for optimising the workflow and ensuring that resources are utilised effectively.

Enhanced Cost Estimation Accuracy

Achieving enhanced cost estimation accuracy is crucial for optimising production planning and resource allocation in manufacturing facilities. Accurate cost estimation is foundational to efficient production planning, as it enables manufacturers to make informed decisions regarding material procurement, labour allocation, and equipment utilisation.

By leveraging advanced fabrication quoting software, manufacturers can enhance cost estimation accuracy through the integration of real-time pricing data, historical cost analysis, and predictive modelling. This technology enables precise forecasting of production costs, taking into account variables such as material fluctuations, labour rates, and overhead expenses.

Accuracy enhancement in cost estimation empowers manufacturing facilities to mitigate financial risks, minimise production delays, and maintain competitive pricing strategies. Furthermore, it facilitates better negotiation with suppliers and clients, as well as improved budget allocation for upcoming projects.

Ultimately, the implementation of advanced fabrication quoting software leads to a more streamlined and efficient production workflow, driving overall operational excellence and profitability.

Real-time Material and Labour Tracking

Enhancing cost estimation accuracy through advanced fabrication quoting software lays the foundation for efficient production planning, which can be further optimised by implementing real-time material and labour tracking.

Implementing real-time material and labour tracking provides numerous benefits, including:

-

Inventory management: Real-time tracking enables businesses to maintain optimal inventory levels by providing visibility into material usage and identifying when reordering is necessary. This helps prevent stockouts and overstock situations, ultimately reducing carrying costs and improving cash flow.

-

Productivity analysis: Tracking labour in real time allows for detailed productivity analysis. By monitoring the time spent on each task and comparing it to the estimated time, businesses can identify inefficiencies, optimise workflows, and allocate resources more effectively.

-

Cost control: Real-time tracking of material usage and labour allows for accurate cost control. Businesses can monitor actual costs against estimates, identify discrepancies early on, and make necessary adjustments to stay on budget.

Seamless Integration With Cad/Cam Systems

Implementing seamless integration with Cad/Cam systems has several benefits for manufacturers. It streamlines the transfer of design data, optimising production planning and enhancing overall operational efficiency. By ensuring CAD/CAM compatibility, fabrication quoting software can directly import design files, eliminating the need for manual data input or conversion. This reduces the likelihood of errors caused by manual input and accelerates the entire production planning process.

Seamless integration with CAD/CAM systems also allows for real-time synchronisation of design changes. This ensures that the most current information is always used for production planning. Moreover, this level of integration enables automatic generation of manufacturing instructions based on the design data. This saves valuable time and resources.

Furthermore, CAD/CAM compatibility facilitates the seamless transfer of production plans to the manufacturing floor. This fosters a more efficient and streamlined production process. Manufacturers can exercise greater control over the production planning and execution processes, leading to improved productivity and cost savings.

Automated Quoting and Proposal Generation

An essential component of fabrication quoting software is its ability to automate the generation of quotes and proposals, significantly streamlining the quoting process for manufacturing businesses.

-

Automated Quoting: Fabrication quoting software enables the automation of the quoting process, allowing for quick and accurate generation of quotes based on predefined parameters, such as material costs, labour, and overhead expenses. This automation eliminates the need for manual calculations, reducing the likelihood of errors and saving valuable time.

-

Competitive Edge: By utilising automated quoting features, manufacturing businesses can respond to customer enquiries with speed and precision, giving them a competitive edge in the market. The ability to provide timely and accurate quotes can enhance customer satisfaction and help win more business opportunities.

-

Proposal Generation: In addition to automating the quoting process, fabrication quoting software facilitates the generation of professional and comprehensive proposals. This feature enables businesses to present detailed project plans, cost breakdowns, and timelines, showcasing their capability and commitment to delivering high-quality products and services.

Incorporating automated quoting and proposal generation capabilities into the fabricating process can significantly improve operational efficiency, enhance customer satisfaction, and contribute to the overall success of manufacturing businesses.

Improved Resource Utilisation and Scheduling

Utilising automated quoting and proposal generation features, fabrication quoting software optimises resource utilisation and scheduling, allowing manufacturing businesses to efficiently allocate materials and labour for production. This improved efficiency is achieved through the software’s ability to analyse current inventory levels, project requirements, and available workforce to generate optimised production schedules. By streamlining resource allocation, production scheduling becomes more precise, reducing downtime and minimising production bottlenecks.

Fabrication quoting software enables businesses to make informed decisions regarding resource optimisation, ensuring that materials and labour are utilised to their full potential. This not only increases productivity but also reduces waste and unnecessary overhead costs. Moreover, the software provides real-time visibility into resource availability, allowing for quick adjustments to production schedules in response to changing demands or unforeseen circumstances.

With improved resource utilisation and scheduling, manufacturing businesses can enhance their operational performance, meet customer demands more effectively, and maintain a competitive edge in the market. Ultimately, fabrication quoting software empowers businesses to achieve greater control over their production processes, leading to higher efficiency and profitability.

Frequently Asked Questions

Can the Fabrication Quoting Software Handle Custom or Specialised Materials That Are Not Commonly Used in Standard Production Processes?

Custom material handling is a crucial aspect for fabrication quoting software. It should seamlessly integrate specialised material compatibility, enabling efficient production planning for non-standard materials. This capability ensures comprehensive and accurate quoting for diverse project requirements.

What Level of Technical Support and Training Is Provided for Implementing and Using the Fabrication Quoting Software?

For technical implementation, our team provides comprehensive support to seamlessly integrate the fabrication quoting software into your existing systems. User training is tailored to equip your team with the necessary skills for proficient operation.

How Does the Software Handle Changes to Project Specifications or Requirements During the Quoting and Production Planning Process?

The software effectively manages changes to project specifications during the quoting and production planning process. Its capabilities include efficient handling of modifications, seamless material management, robust technical assistance, comprehensive report generation, and stringent data security measures.

Can the Software Generate Reports and Analytics to Track Production Efficiency and Identify Areas for Improvement?

Yes, the software is equipped to generate comprehensive reports and analytics for production tracking and efficiency analysis. This allows for real-time monitoring of production processes, identification of bottlenecks, and optimisation of resource allocation for continuous improvement.

What Security Measures Are in Place to Protect Sensitive Data and Intellectual Property Within the Software System?

Data security within the system is ensured through robust encryption, role-based access control, and regular security audits. Intellectual property protection measures include restricted access to sensitive information and comprehensive data backup protocols.

Conclusion

In conclusion, fabrication quoting software plays a crucial role in optimising production planning and workflow. Its ability to streamline processes, enhance cost estimation accuracy, and track materials and labour in real-time makes it an essential tool for efficient manufacturing operations.

Additionally, the software’s integration with Cad/Cam systems allows for seamless transfer of data, eliminating the need for manual input and reducing errors.

Furthermore, the automation of quoting and proposal generation saves time and resources, allowing companies to respond quickly to customer demands.

Lastly, the software’s ability to improve resource utilisation and scheduling ensures that production is running at maximum efficiency, leading to higher productivity and cost savings.

By embracing this technology, companies can achieve higher productivity, cost savings, and overall operational efficiency.

Contact us to discuss our services now!